At 5BChem, we specialize in high-performance chemical solutions, offering advanced polyurethane systems and additives designed to meet the needs of diverse industries. From footwear manufacturing to rigid and flexible foam applications, our innovative products prioritize sustainability and efficiency.

About Us

Building Bridges for Chemical Excellence

5BChem is a leader in manufacturing specialized polyurethane systems and additives, enabling industries to meet their

production goals with efficiency and innovation. We focus on delivering sustainable solutions tailored to the unique

needs of each client.

Vision

To build a global brand that reflects the core values of belief, balance, bravery, betterment, and brilliance, focusing on delivering innovative, human-centric solutions across multiple sectors, including footwear

Mission

To provide innovative chemical solutions for industrial and commercial sectors, focusing on advanced technologies that prioritize sustainability and efficiency in the UAE and global markets.

Core Values

Believe

In the transformative power of cutting-edge chemical technologies.

Balance

Developing products that achieve optimal performance without compromising safety or the environment.

Brave

Exploring and adopting pioneering technologies to meet the UAE’s growing industrial needs.

Better

Offering products that lead to better operational efficiencies and cost savings for clients.

Bright

Advancing chemical research to stay at the forefront of industry developments.

Director's Message

Dr. Hamid Islam

– Dr. Hamid Islam

500+

HAPPY CLIENTS

100%

SATISFACTION

8

PRODUCTS

5+

YEARS IN BUSINESS

Our Products

Explore Our High-Performance Polyurethane Solutions

We offer a range of innovative products designed to enhance industrial applications:

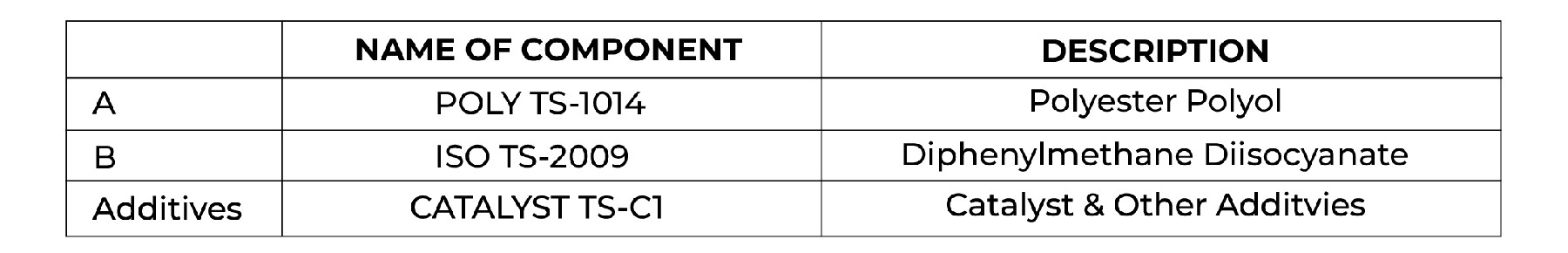

POLYURETHANE FOR REGULAR SLIPPER SYSTEM

Poly TS-1014 / ISO TS-2009

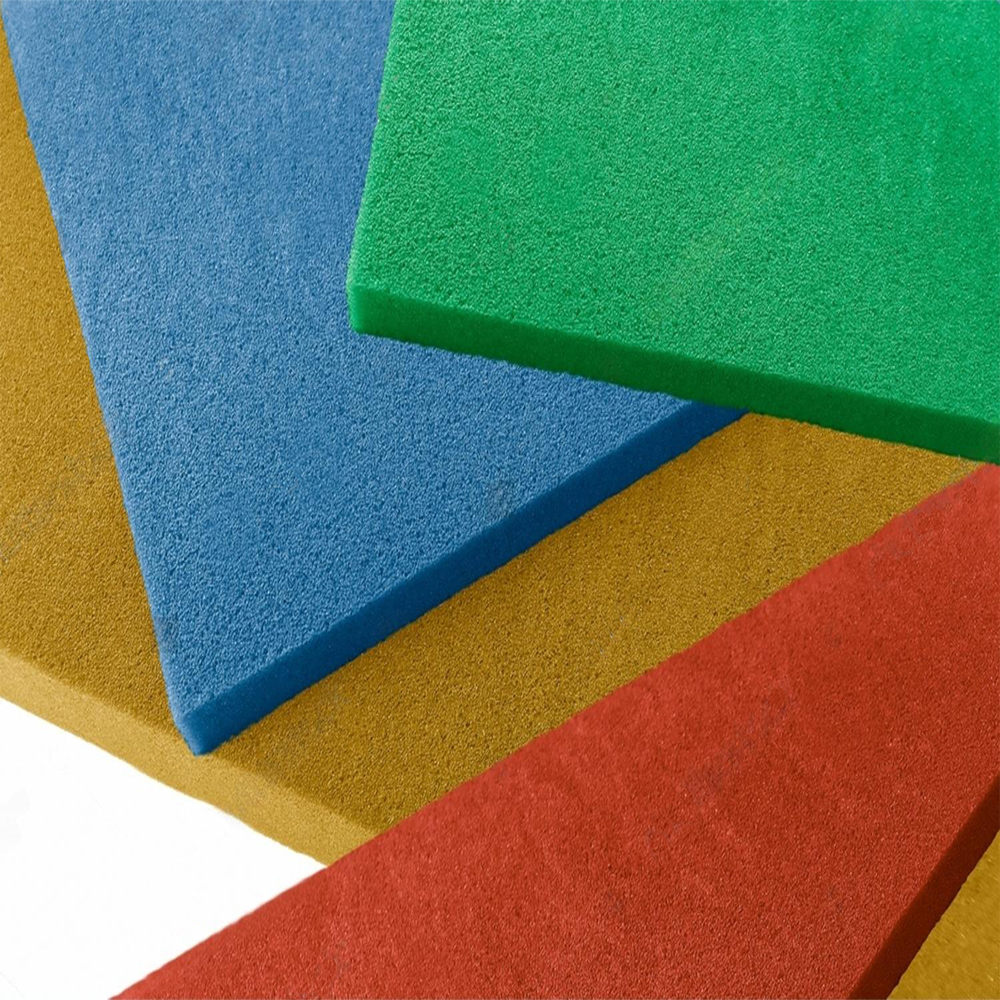

These are polyurethane systems at various hardness and density values with high flex resistance which are used in slipper and shoe manufacturing.

COMPONENTS

CATALYST & ADDITIVES

The adding amount of TS-C1 should be 3200 ± 200g / 220kg, the adding amount of hardener should be 600-1000g / 220kg

APPLICATION AREA

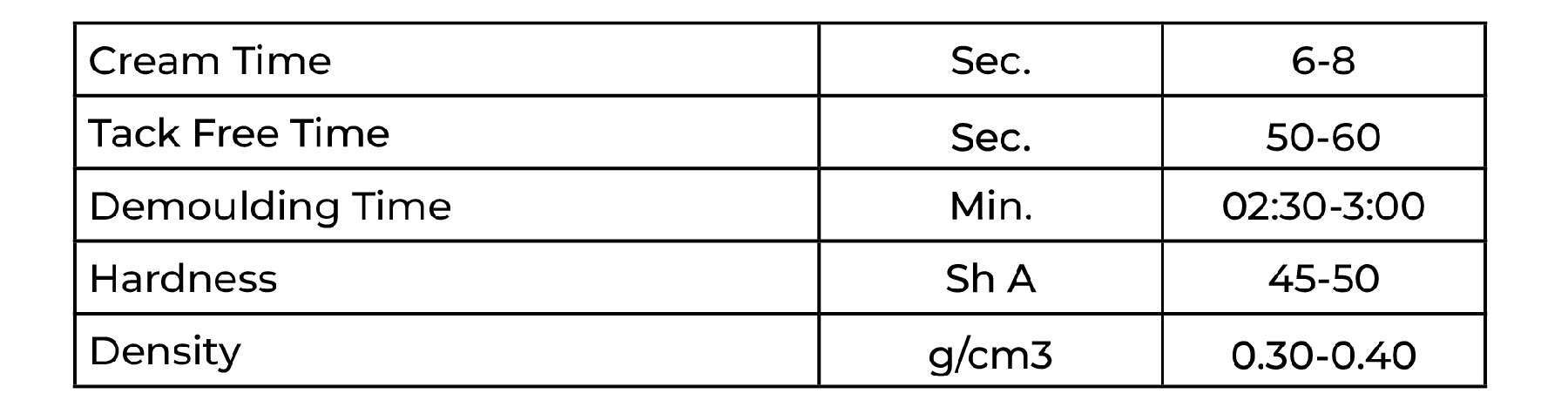

OPERATING CONDITIONS

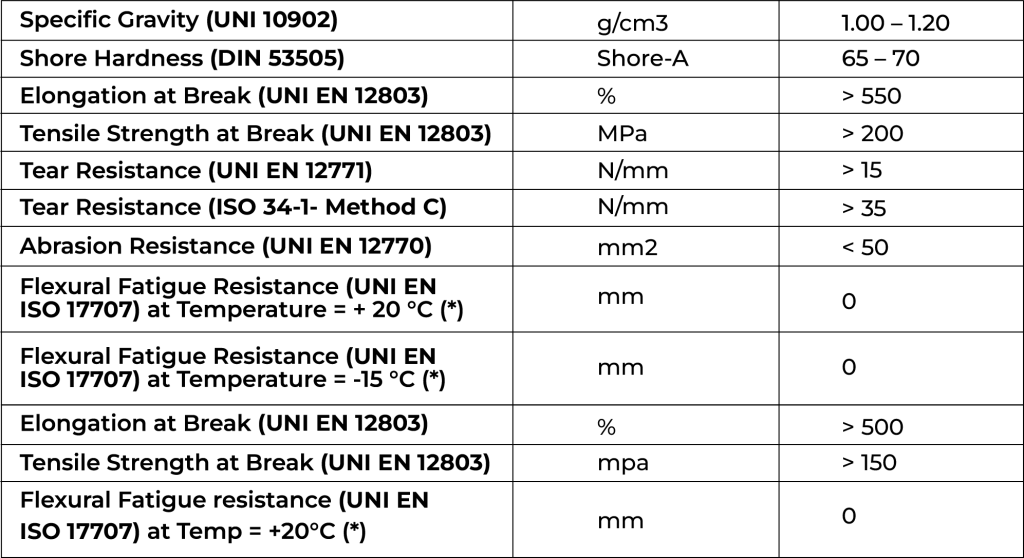

MECHANICAL PROPERTIES

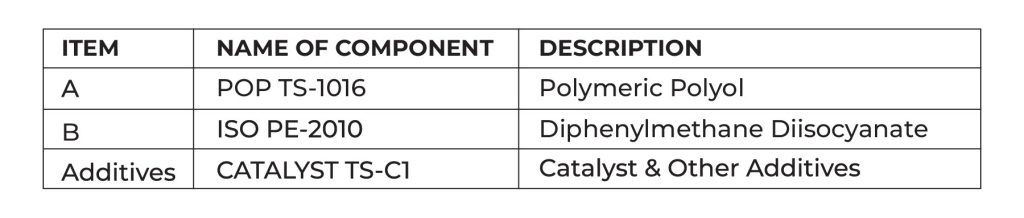

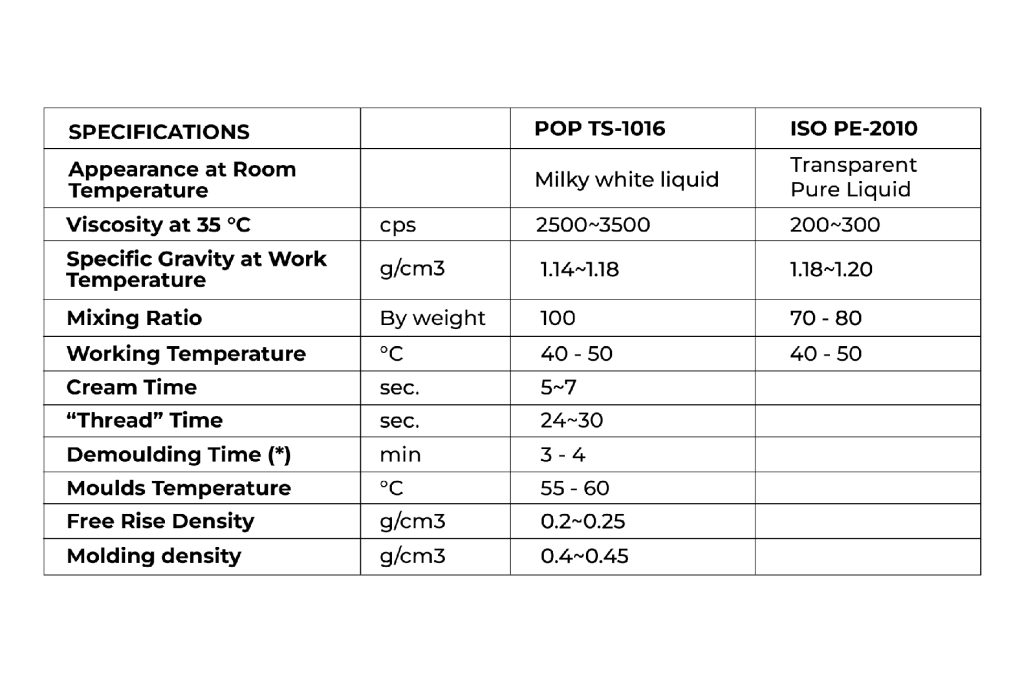

POLYURETHANE FOR

FLEXIBLE SHOES

POP TS-1016 / ISO PE-2010

Polyurethane Three-Component System

CATALYST & ADDITIVES

The adding amount of TS-C1 should be 3200±200g/220kg, the adding amount of hardener should be 7000g ±50g/220kg, the adding amount of water should be 500±100g/220kg.

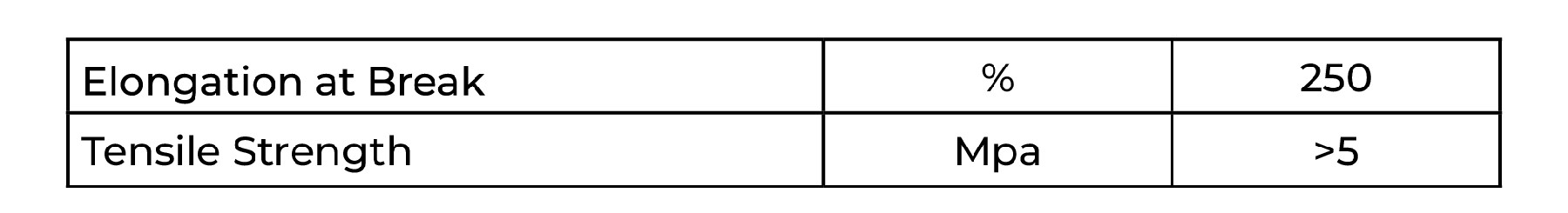

MECHANICAL PROPERTIES

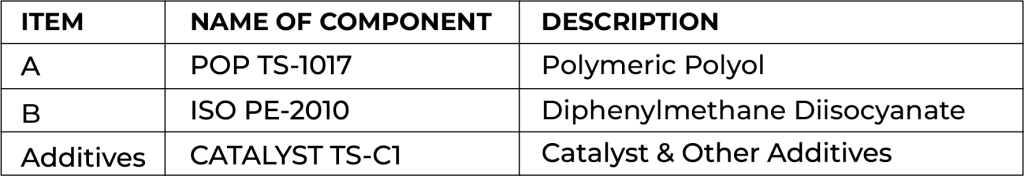

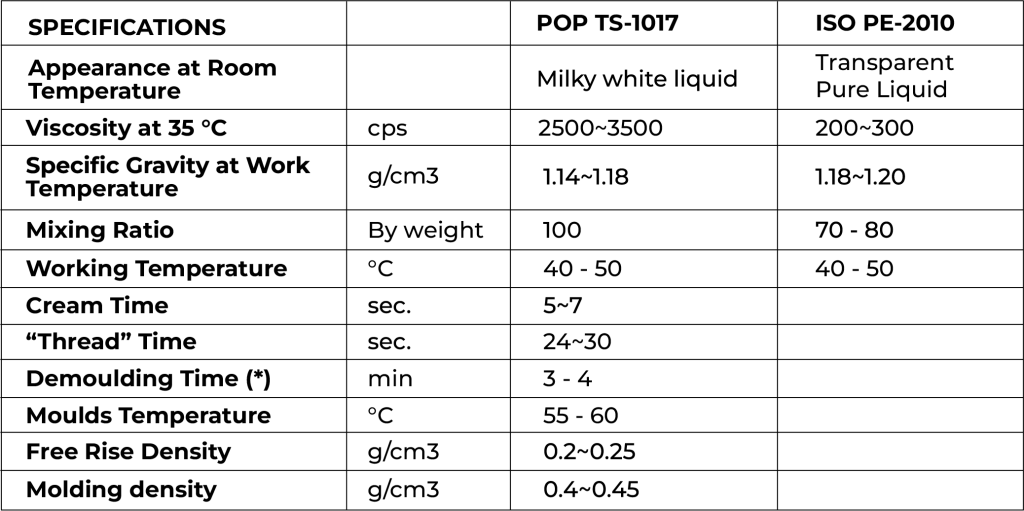

POLYURETHANE FOR

FLEXIBLE SHOES

POP TS-1017 / ISO PE-2010

Polyurethane Three-Component System

CATALYST & ADDITIVES

The adding amount of TS-C1 should be 3200±200g/220kg, the adding amount of hardener

should be 7000g ±50g/220kg, the adding amount of water should be 500±100g/220kg.

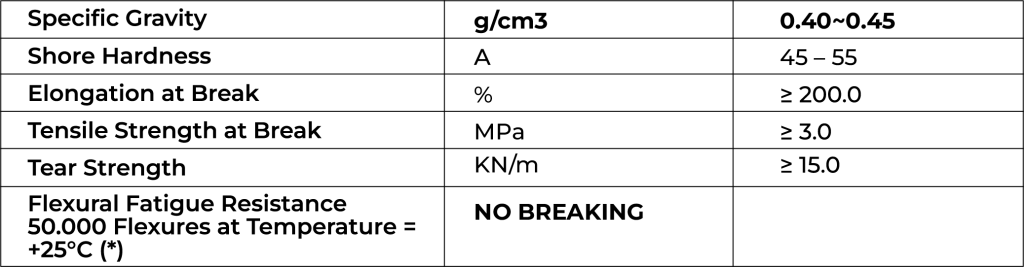

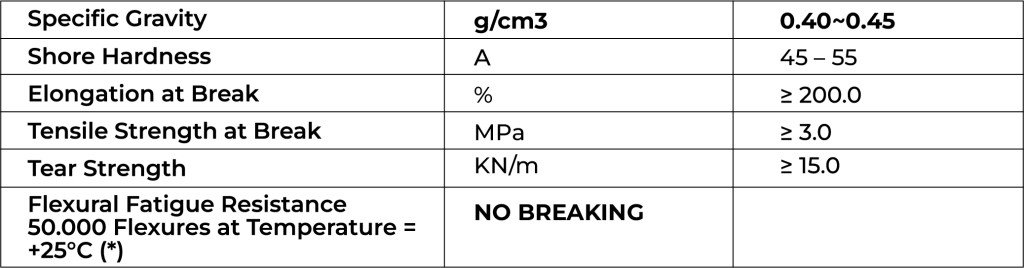

MECHANICAL PROPERTIES

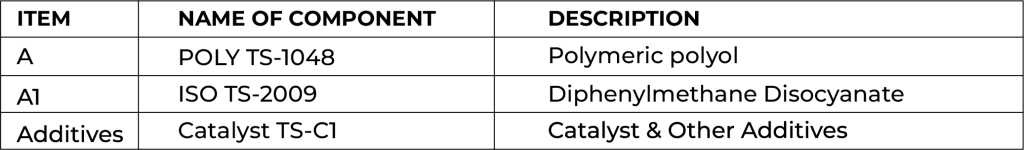

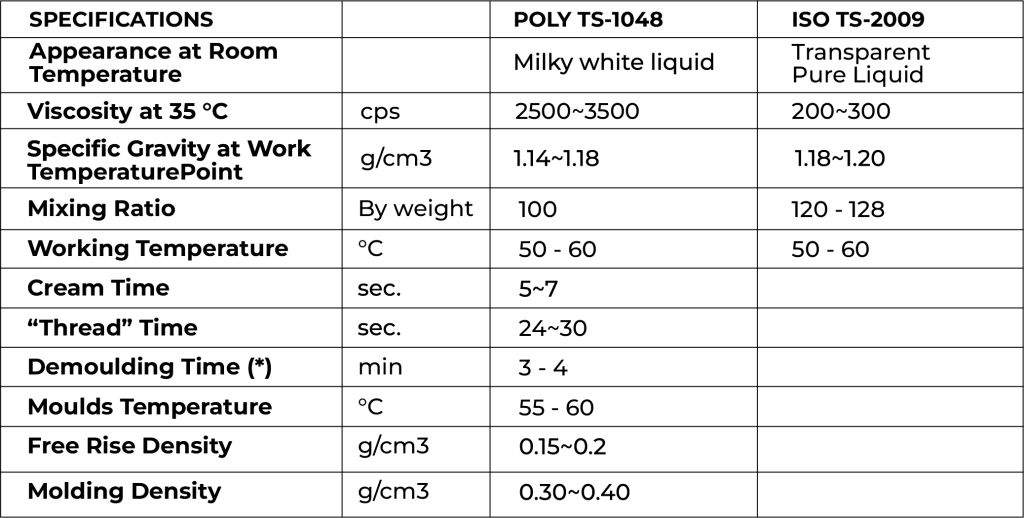

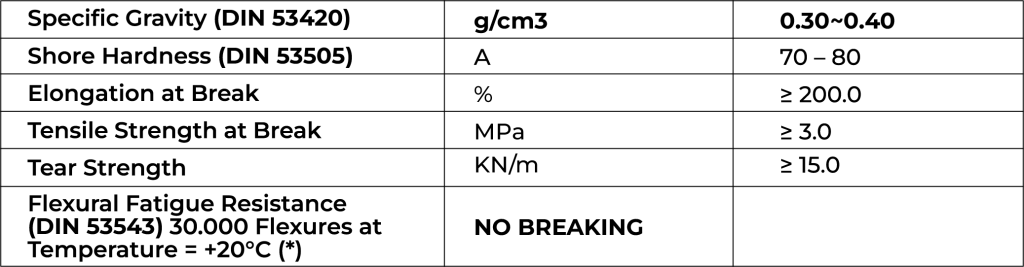

POLYURETHANE FOR

HARD SOLE SHOES

POLY TS-1048 / ISO TS-2009

Polyurethane Three-Component System

COMPONENTS

MECHANICAL PROPERTIES OF THE FOAM

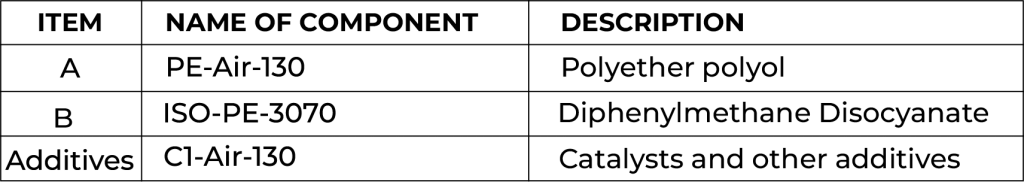

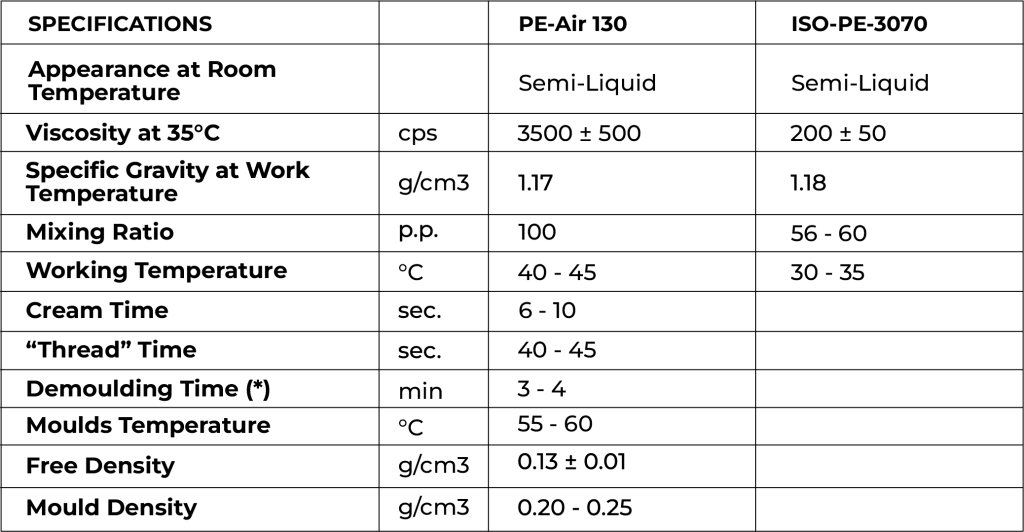

POLYURETHANE FOR

INSOLE

PE-Air 130 / ISO-PE-3070

COMPONENTS

MECHANICAL PROPERTIES OF THE FOAM

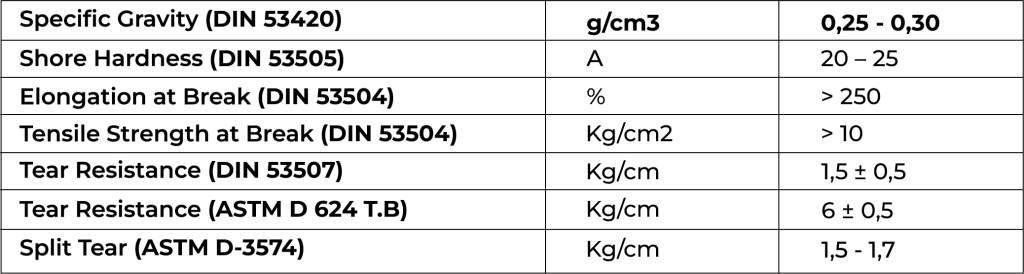

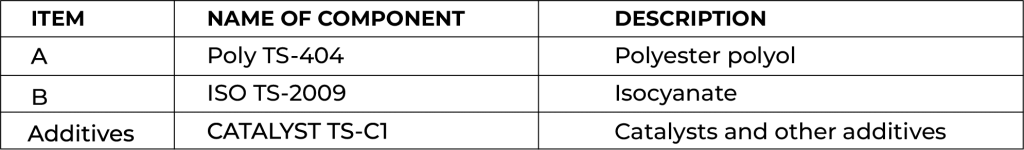

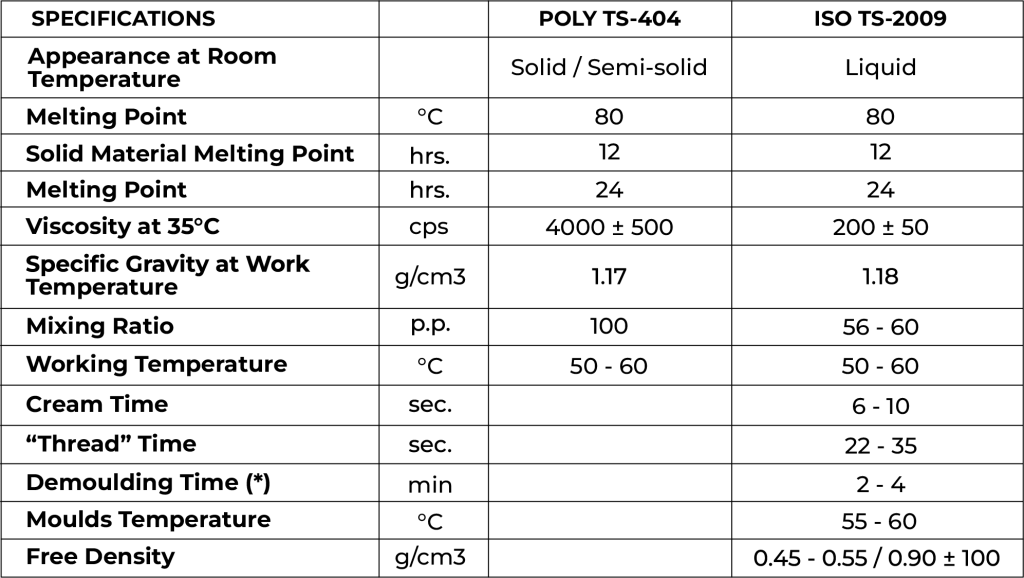

POLYURETHANE FOR

SAFETY SHOES

Poly TS-404 / ISO TS-2009

Polyurethane Three-Component System

COMPONENTS

MECHANICAL PROPERTIES OF THE FOAM

Additive for Slab Stock Foam

Catalyst TS-A1

Catalyst TS-A1 is a tertiary amine which has a strong influence on the urea (water isocyanate) reaction in flexible and rigid polyurethane foams.

Key Features and Benefits

- Multi-purpose amine Catalyst.

- Strong gelation catalyst.

- Easy Handling.

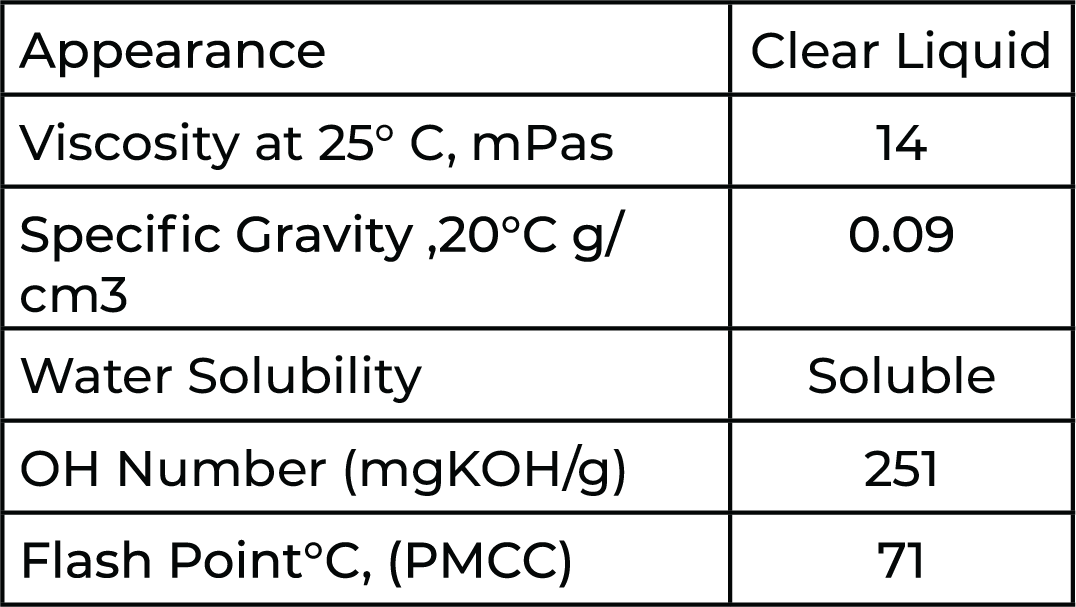

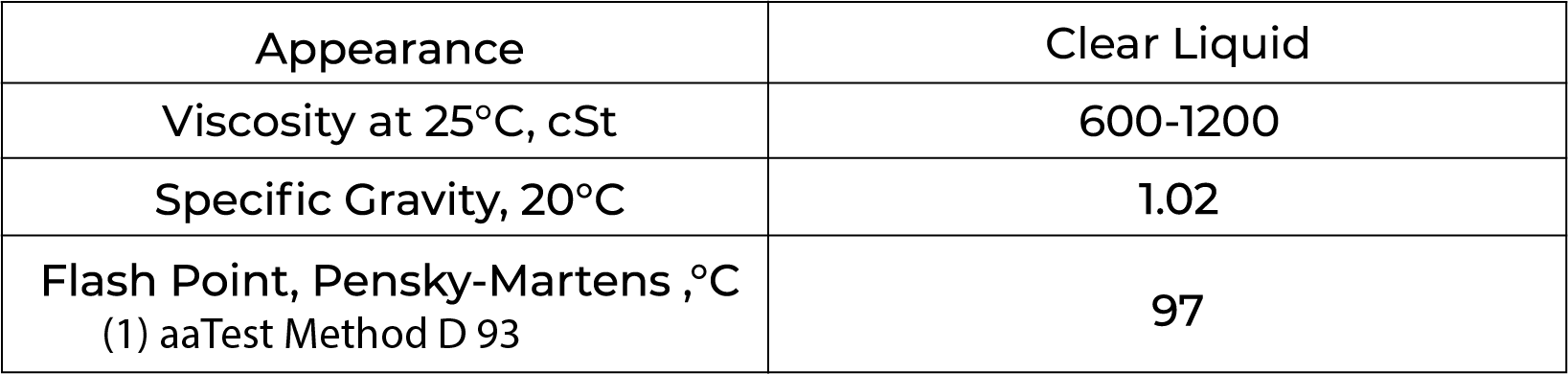

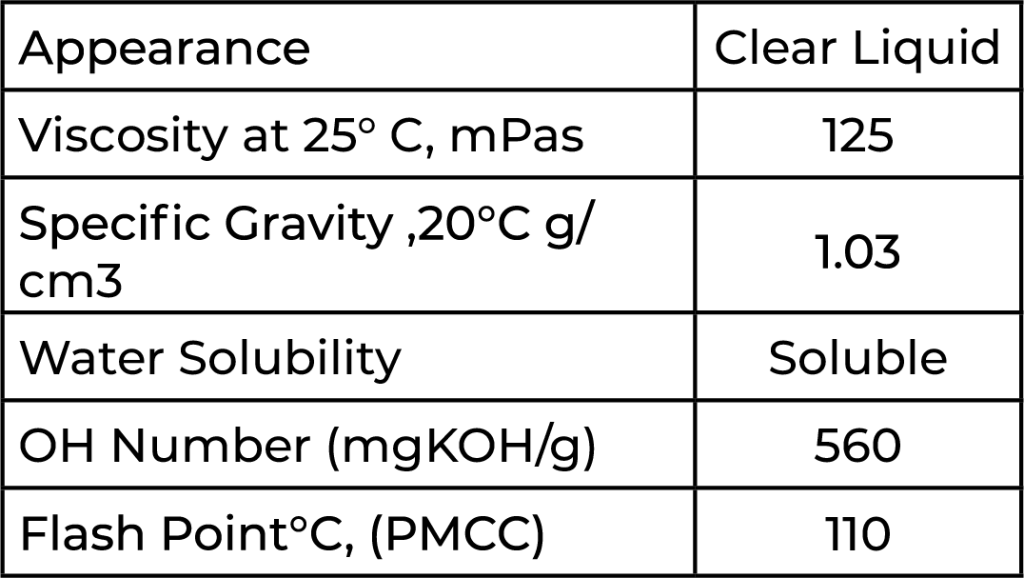

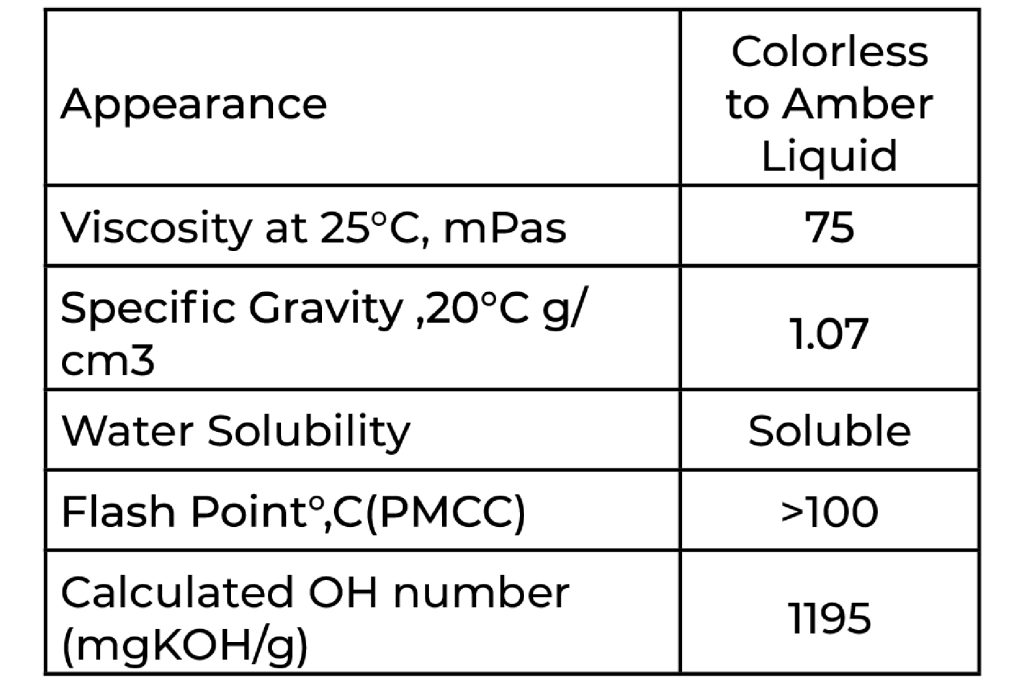

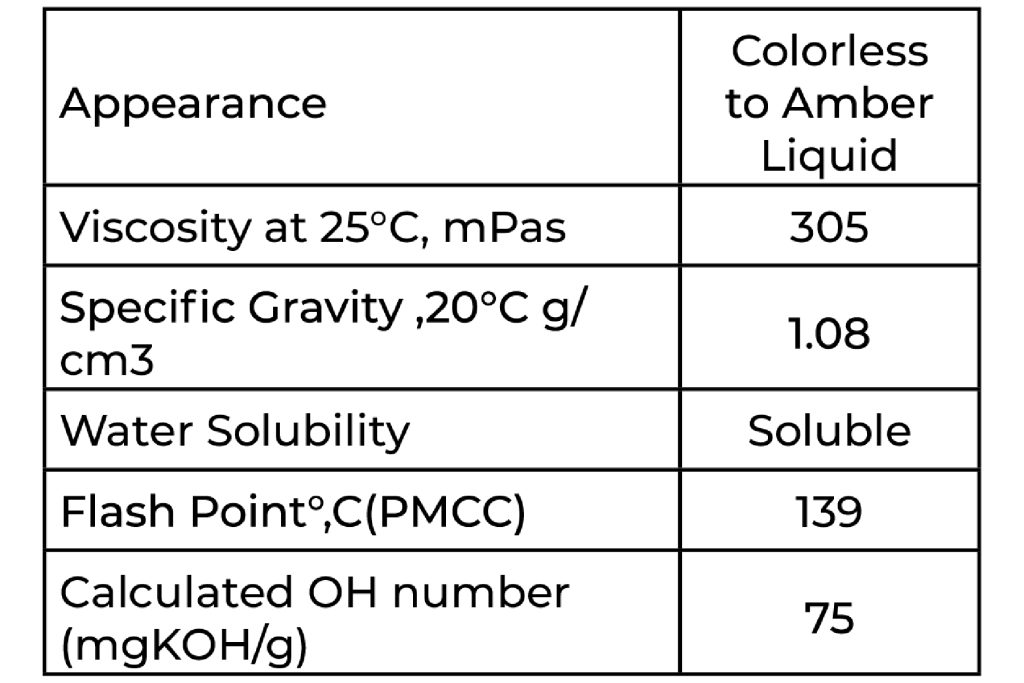

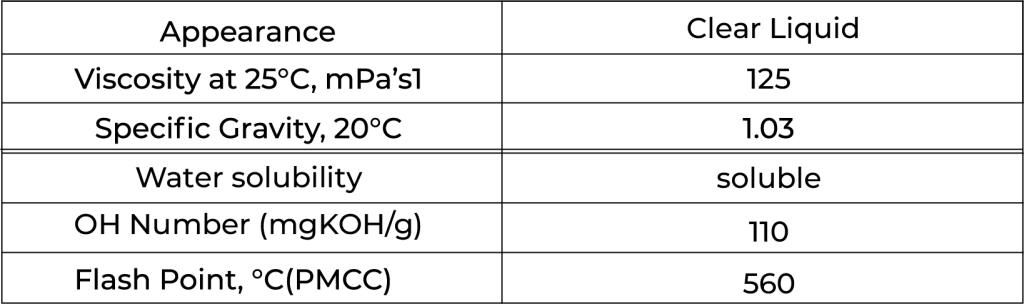

Typical Physical Properties

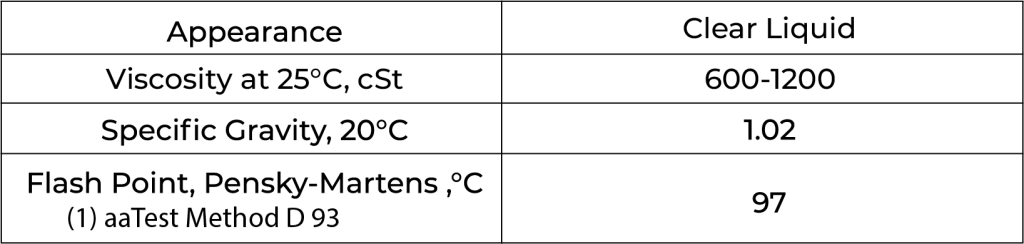

SILICONE

TR-L580

Silicone TR-L580 is a non-hydrolyzable silicone, designed to provide excellent foam stability and fine regular cell structure in extremely low density foams using liquid carbon dioxide as the blowing agent. In stretched formulations with high TDI, high water, high CO2, Silicone

TR-L580 provides superior nucleating efficiency and dramatically reduces striations in the foam bun. It has full hydrolytic stability and can be used as a separate stream or in water/ amine/ silicone preblends. Silicone TR-L580 offers enhanced stability while yielding foams with good breathability.

KEY FEATURES & BENEFITS

• Silicone with medium efficiency

• Excellent foam stability plus good breathability in low-density formulations blown with liquid carbon dioxide Complete hydrolytic stability in water/amine/silicone preblends

• Works well on all commercially available CO2 equipment (Cardio/Beamech/Novaflex)

TYPICAL PHYSICAL PROPERTIES

There was, of course, some variability of operating parameters during sample production, but, in most cases, differences were quite small. The exception to this was that a significant throughput difference was required with the Beamech equipment, with the two different polyols. The higher viscosity of the 3500MW polyol required that we increase the surface area

of the sinter (which controls pressure at the lay-down) because pressure was higher than desired. This pressure is the key operating parameter for froth and cell structure control at any given CO2 concentration. Since surface area can only be changed in discrete increments, the resulting pressure was too low at the same throughput used for the 3000MW polyol.

Therefore, it was necessary to significantly increase total throughput to maintain pressure at the desired level. The throughput with 3000MW polyol averaged 11 kg/min, while it averaged almost 19 kg/min using the 3500MW material. For the Novaflex and Cardio equipments, throughput with 3000MW polyol was 14 kg/min and 16 kg/min for the 3500MW material.

PRODUCT SAFETY, HANDLING & STORAGE

Customers considering the use of this product should review the latest Material Safety Data Sheet and label of the product for safety instructions. If you require Technical Data Sheet or Material Safety Data Sheet of any product, please send a request to hamid@waresagroup.com,

we would share the relevant documentation.

LIMITATIONS

Customers must evaluate our Performance Materials products and make their own determination as to fitness of use in their particular applications.

SHELF LIFE

Additive for Slab Stock Foam

Catalyst TS-A33

Catalyst TS-A33 is a tertiary amine, which has a strong influence on promoting the urethane (polyol isocyanate) reaction in a variety of flexible and rigid foam as well as in case applications.

Key Features and Benefits

- Multi-purpose amine Catalyst.

- Strong gelation catalyst.

- Easy Handling.

Typical Physical Properties

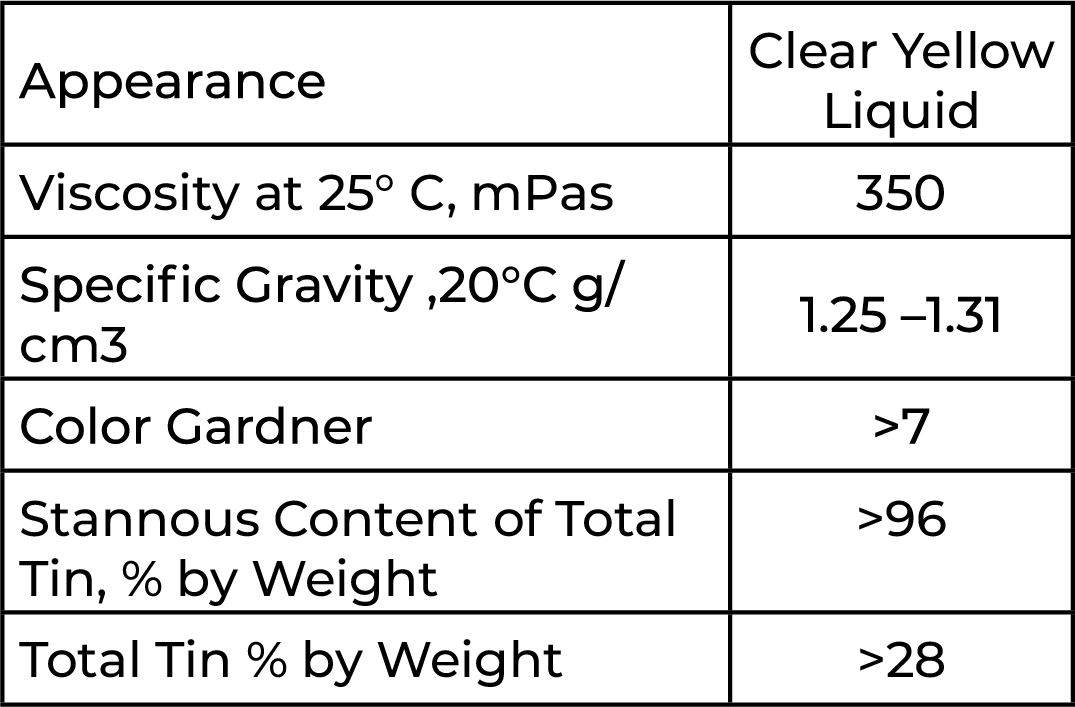

Additive for Slab Stock Foam

Catalyst TS-T9

Tin Catalyst TS-T9 (Stannous Octoate) is designed for use in flexible urethane applications. It is a clear, colorless light yellow fluid with low viscosity and excellent solubility in polyether polyols. TS-T9 is widely accepted as the “benchmark” catalyst in the production of flexible polyether urethane foams due to its exceptional capability of promoting the isocyanate- hydroxyl reaction

Key Features and Benefits

- Provides excellent high quality, uniform flexible foam

- Its usage ensures economical, high-speed, high- volume foam production

- Provides high gel catalyst activity performance

Typical Physical Properties

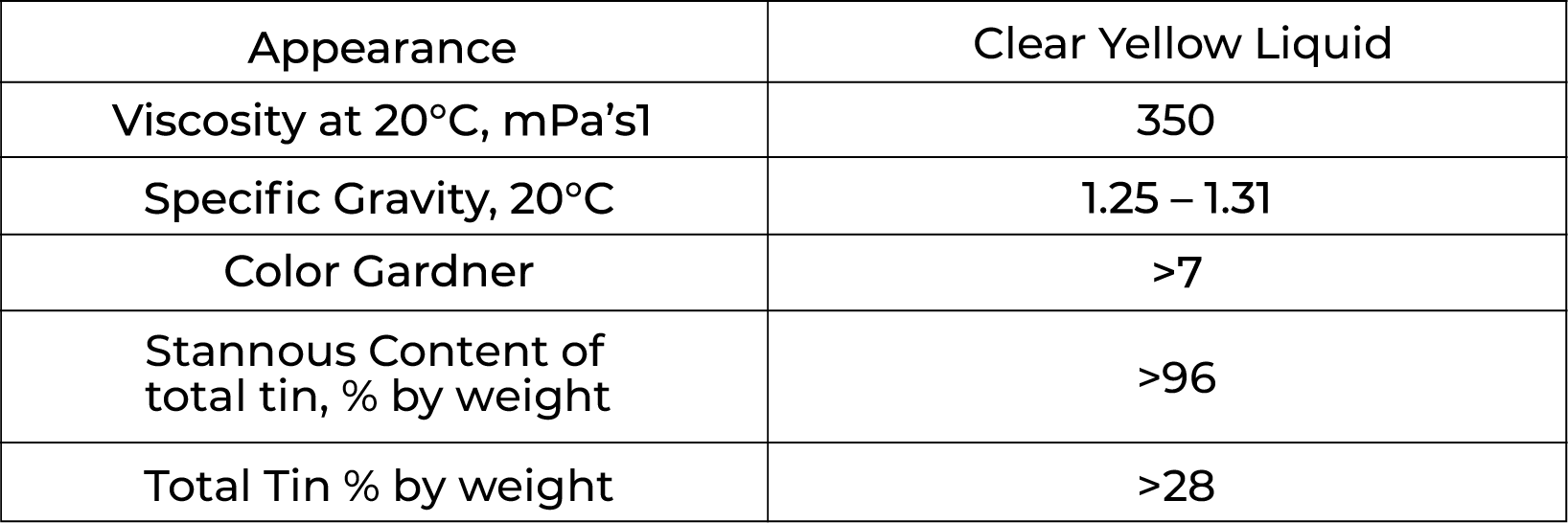

CATALYST

TR-T9

Tin Catalyst TR-T9 (Stannous Octoate) is designed for use in flexible urethane applications. It is a clear, colorless to light yellow fluid with low viscosity and excellent solubility in polyether polyols and most organic solvents. TR-T9 is widely accepted as the “benchmark” catalyst in the production of flexible polyether urethane foams due to its exceptional capability of promoting the isocyanate-hydroxyl reaction.

Key Features and Benefits

- Provides excellent high quality, uniform flexible foam

- Its usage ensures economical, high-speed, high-volume foam production

- Provides high gel catalyst activity performance

Typical Physical Properties

NOTE

(Catalyst TR-T9 is sensitive to oxidation and should be kept in closed containers, in a dry place. Once the package is opened, it should be used as quickly as possible. When it is diluted into

polyol, the solution should be used the same day)

PRODUCT SAFETY, HANDLING AND STORAGE

Customers considering the use of this product should review the latest Material Safety Data Sheet and label of the product for safety instructions. If you require Technical Data Sheet or Material Safety Data Sheet of any product, please send a request to hamid@waresagroup.com, we would share the relevant documentation

LIMITATIONS

Customers must evaluate our Performance Materials products and make their own determination as to fitness of use in their particular applications.

SHELF LIFE

12 months/date of manufacture

Additive for Slab Stock Foam

Silicon TS-L580

Silicone TS-L580 is a non-hydrolyzable silicone, designed to provide excellent foam stability and fine regular cell structure in extremely low density foams using liquid carbon dioxide as the blowing agent. In stretched formulations with high TDI, high water, high CO2, Silicone TS-L580 provides superior nucleating efficiency and dramatically reduces striations in the foam bun.

Key Features and Benefits

- Silicone with medium efficiency

- Excellent foam stability plus good breathability in low- density formulations blown withnliquid carbon dioxide

- Complete hydrolytic stability in water/amine/silicone preblends

- Works well on all commercially available CO2 equipment (Cardio/Beamech/Novaflex)

Typical Physical Properties

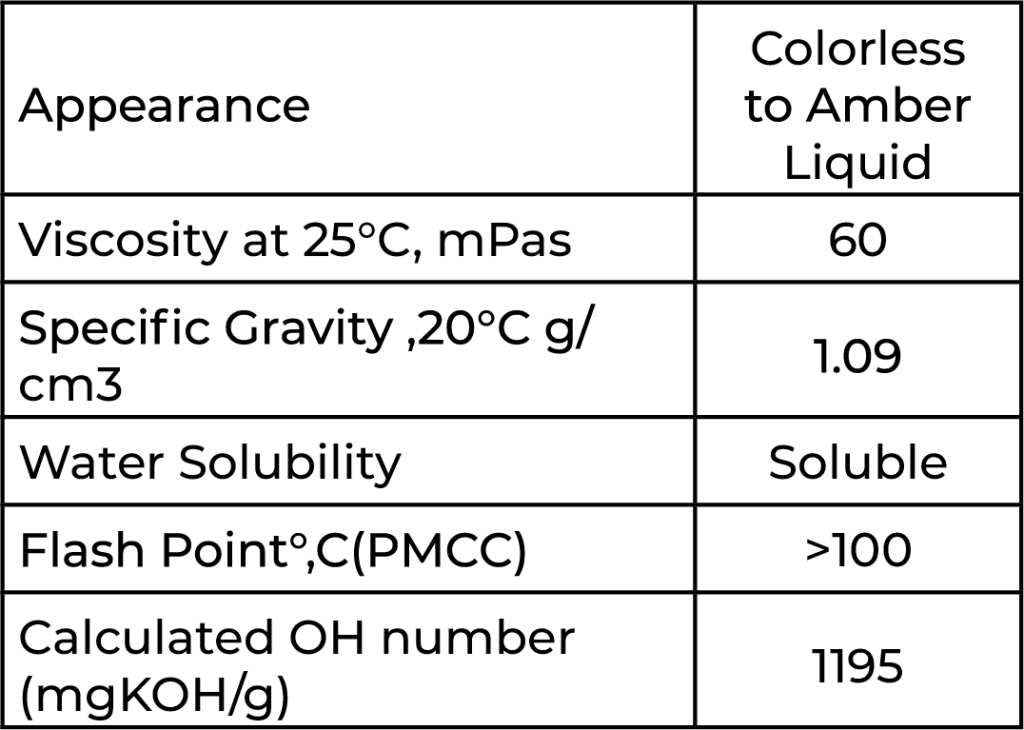

Additive for Shoe Grade PU

Catalyst TS-EG

TS-EG catalyst is a tertiary amine that is a strong urethane (polyol-isocyanate) catalyst that can be used in flexible foam applications and is commonly used for shoe soles.

Key Features and Benefits

- Strong gelation catalysis

- Convenient liquid form

Typical Physical Properties

Additive for Shoe Grade PU

Catalyst TS-1027

TS-1027 is a modified triethylenediamine solution and a structurally delayed tertiary amine catalyst. It can delay the Milky time and increase the early liquidity; Accelerate the curing of the rear end, shorten the demoulding time and improve the production efficiency; Improve the fluidity of the system, improve the dimensional stability of foam, avoid product shrinkage, and have high catalytic effect on the reaction between polyols and isocyanates. It is an amine fast demoulding catalyst developed for polyester and polyether microporous sole and self-skinning foam system.

Key Features and Benefits

- Extremely high reactivity in microcellular systems.

- Increased processing flexibility due to shorter demold time.

Typical Physical Properties

Additive for Shoe Grade PU

Catalyst TS-193

TS-193 surfactant is the industry standard silicone surfactant for most conventional rigid polyurethane foam and shoe sole systems. It provides excellent flame retardant properties in rigid foam applications and excellent cell structure in the shoe sole applications.

Key Features and Benefits

- Proven performance in most rigid foam applications, laminated panels.

- Spray foam, pouring-place systems, packaging and bun stock Increased.

- Microcellular foam systems: footwear(shoe soles), integral skin.

Typical Physical Properties

CATALYST TR-A33

Catalyst TR-A33 is a tertiary amine, which has a strong influence on promoting the urethane

(polyol isocyanate) reaction in a variety of flexible and rigid foam as well CASE applications.

Key Features and Benefits

- Multi-purpose amine Catalyst.

- Strong gelation catalyst.

- Easy Handling

Typical Physical Properties

There was, of course, some variability of operating parameters during sample production, but, in most cases, differences were quite small. The exception to this was that a significant throughput difference was required with the Beamech equipment, with the two different polyols. The higher viscosity of the 3500MW polyol required that we increase the surface area of the sinter (which controls pressure at the lay-down) because pressure was higher than desired. This pressure is the key operating parameter for froth and cell structure control at any given CO2 concentration. Since surface area can only be changed in discrete increments, the resulting pressure was too low at the same throughput used for the 3000MW polyol. Therefore, it was necessary to significantly increase total through put to maintain pressure at the desired level. The throughput with 3000MW polyol averaged 11 kg/min, while it averaged almost 19 kg/min using the 3500MW material. For the Novaflex and Cardio equipments, throughput with 3000MW polyol was 14 kg/min and 16 kg/min for the 3500MW material.

PRODUCT SAFETY, HANDLING AND STORAGE

Customers considering the use of this product should review the latest Material Safety Data Sheet and label of the product for safety instructions. If you require Technical Data Sheet or Material Safety Data Sheet of any product, please send a request to hamid@waresagroup.com, we would share the relevant documentation.

LIMITATIONS

Customers must evaluate our Performance Materials products and make their own determination as to fitness of use in their particular applications.

SHELF LIFE

12 months/date of manufacture

The information contained herein is, to the best of our knowledge and belief, accurate. However, since the conditions of handling and of use are beyond our control, we make no guarantee of results, and assume no liability for the damages incurred by the following these suggestions. Nothing contained herein is to be construed as a recommended for the use in violation of any patents or of applicable laws or regulation

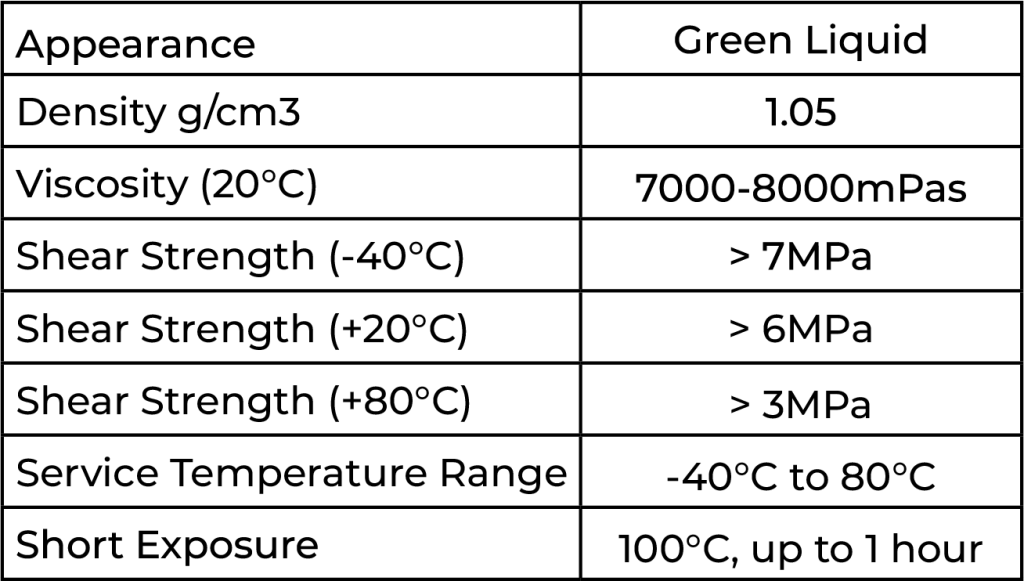

ONE COMPONENT FOAM BINDER 6040

PU Foam binder 6040 is a solvent-free moisture cure one- component adhesive, based on polyurethane technology

Application Areas

The Substance can be bond to one another or to materials. laminated panels, various plastic, rigid doams made for polystyrene, polyurethane and others. The main application area is the manufature of sandwich elements such as partition walls (thermal insulation, sound protection), facade elements with mineral fiber core or mats bonded to primed sheet metal or compression moulding compounds and plaster boards

For faster curing PU binder 6040 can be cured in a heated press.

Maximum temprerature must not exceed 70°C

Properties and Technical Features

Application Areas

– Footwear Manufacturing: Customized polyurethane systems for slippers, flexible shoes, and hard soles.

– Construction: Adhesives and binders for lightweight, durable materials.

– Foam Production: Catalysts and silicones for rigid and flexible foam systems.

Sustainability

– Energy-efficient Production: Streamlined processes to reduce energy consumption.

– Collaborative Growth: Partnering with industries to achieve shared sustainability goals.

12 months/date of manufacture

— Ready to start?

Get in Touch