At 5BChem, we specialize in high-performance chemical solutions, offering advanced polyurethane systems and additives

designed to meet the needs of diverse industries. From footwear manufacturing to rigid and flexible foam applications,

our innovative products prioritize sustainability and efficiency.

About Us

Building Bridges for Chemical Excellence

5BChem is a leader in manufacturing specialized polyurethane systems and additives, enabling industries to meet their

production goals with efficiency and innovation. We focus on delivering sustainable solutions tailored to the unique

needs of each client.

Vision

To build a global brand that reflects the core values of belief, balance, bravery, betterment, and brilliance, focusing on delivering innovative, human-centric solutions across multiple sectors, including footwear

Mission

To provide innovative chemical solutions for industrial and commercial sectors, focusing on advanced technologies that prioritize sustainability and efficiency in the UAE and global markets.

Core Values

Believe: In the transformative power of cutting-edge chemical technologies.

Balance: Developing products that achieve optimal performance without compromising safety or the environment.

Brave: Exploring and adopting pioneering technologies to meet the UAE’s growing industrial needs.

Better: Offering products that lead to better operational efficiencies and cost savings for clients.

Bright: Advancing chemical research to stay at the forefront of industry developments.

Director's Message

Dr. Hamid Islam

At 5B Chem, we are more than just a supplier of Polyurethane additives—we are partners in innovation, helping industries worldwide find solutions that truly matter. From our trusted range of products, like silicone stabilizers and catalysts, to our strong focus on quality, we aim to meet and exceed the unique needs of our customers around the globe.

What sets us apart is our people—a passionate team of researchers and innovators who bring fresh ideas and creativity to every challenge. Together, we are redefining what’s possible in Polyurethane, shaping a brighter and more sustainable future for industries and communities alike.

Guided by our belief in Balance, Bravery, Betterment, Brightness, and the power to Believe, we remain committed to advancing industries, improving lives, and creating a lasting impact on the world around us.” – Dr. Hamid Islam

500+

HAPPY CLIENTS

8

PRODUCTS

100%

SATISFACTION

5+

YEARS IN BUSINESS

Our Products

Explore Our High-Performance Polyurethane Solutions

We offer a range of innovative products designed to enhance industrial applications:

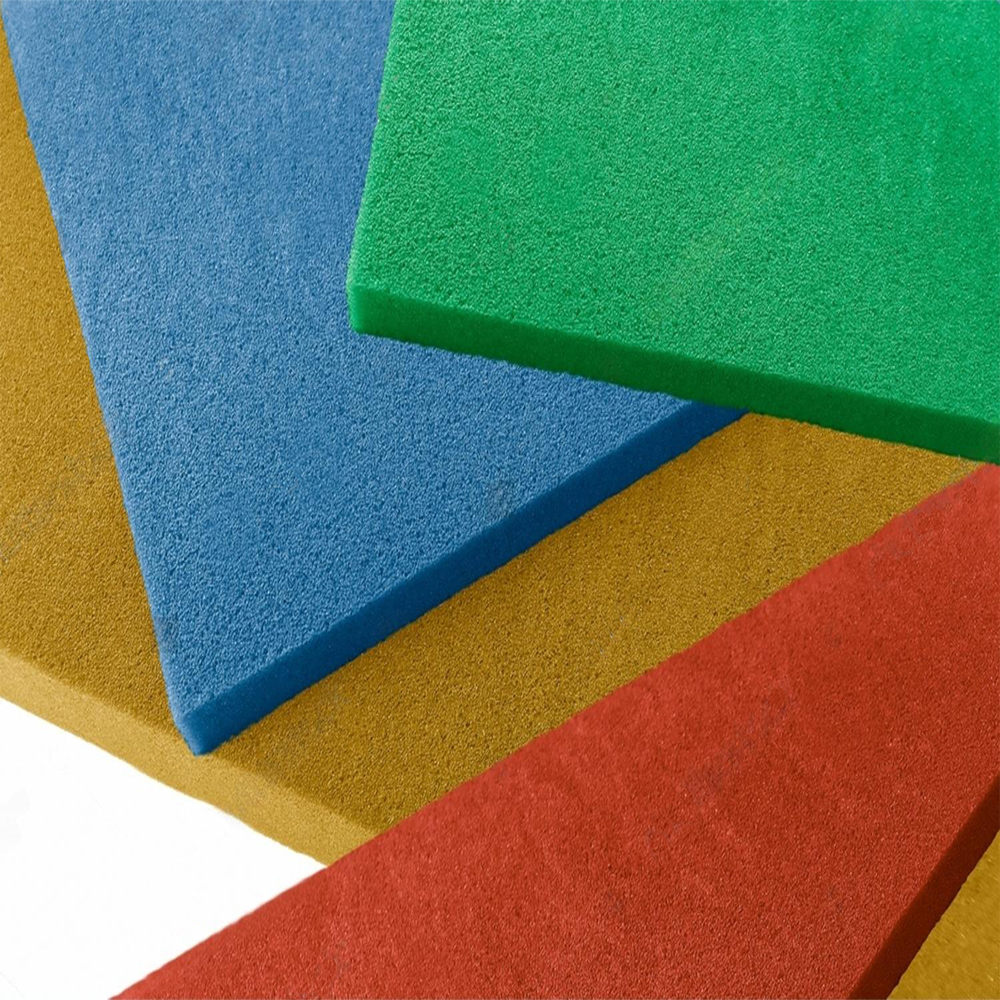

POLYURETHANE FOR REGULAR SLIPPER SYSTEM

Poly TS-1014 / ISO TS-2009

These are polyurethane systems at various hardness and density values with high flex resistance which are used in slipper and shoe manufacturing.

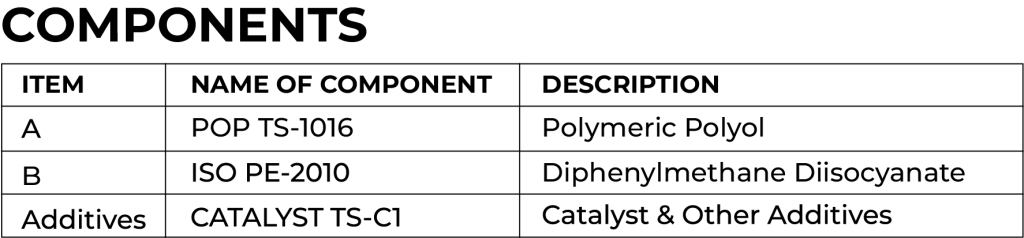

COMPONENTS

CATALYST & ADDITIVES

The adding amount of TS-C1 should be 3200 ± 200g / 220kg, the adding amount of hardener should be 600-1000g / 220kg

APPLICATION AREA

OPERATING CONDITIONS

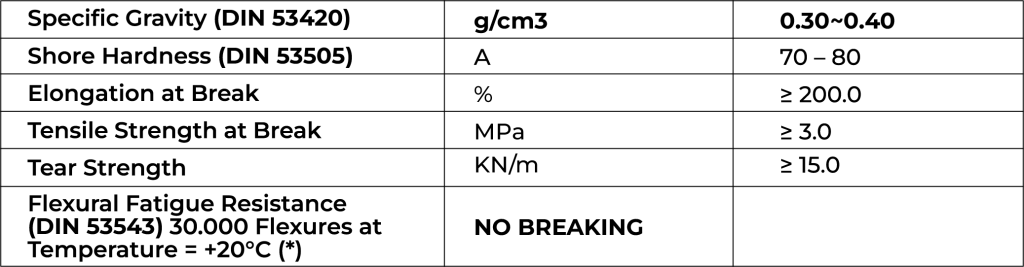

MECHANICAL PROPERTIES

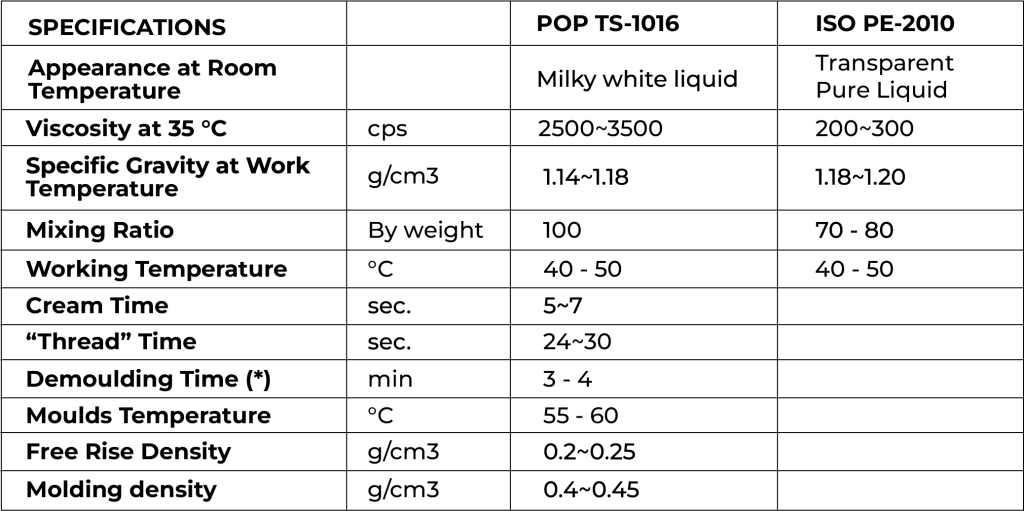

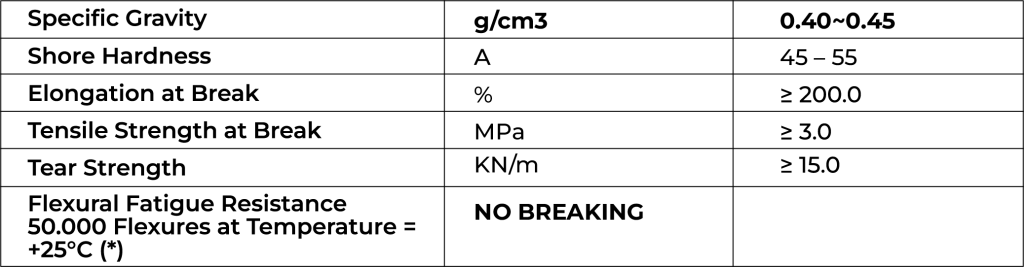

POLYURETHANE FOR

FLEXIBLE SHOES

POP TS-1016 / ISO PE-2010

Polyurethane Three-Component System

CATALYST & ADDITIVES

The adding amount of TS-C1 should be 3200±200g/220kg, the adding amount of hardener should be 7000g ±50g/220kg, the adding amount of water should be 500±100g/220kg.

MECHANICAL PROPERTIES

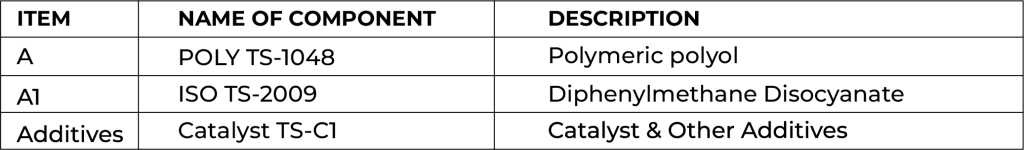

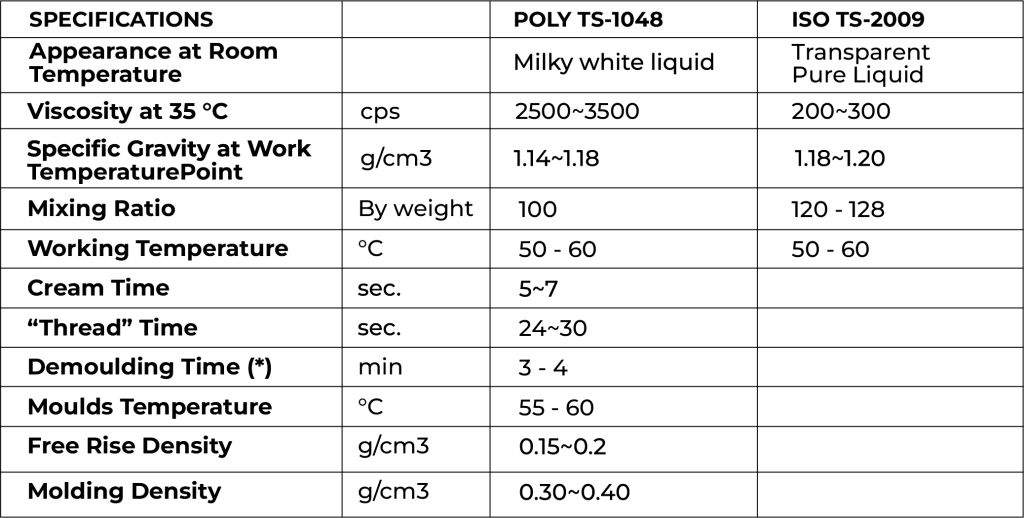

POLYURETHANE FOR

HARD SOLE SHOES

POLY TS-1048 / ISO TS-2009

Polyurethane Three-Component System

COMPONENTS

MECHANICAL PROPERTIES OF THE FOAM

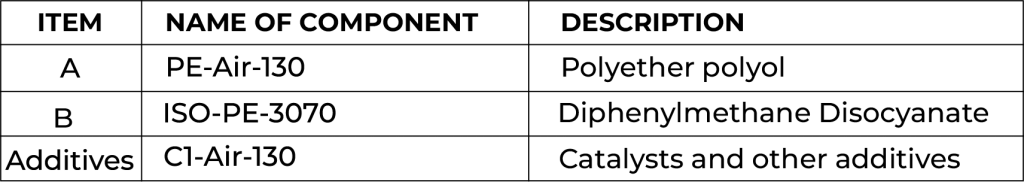

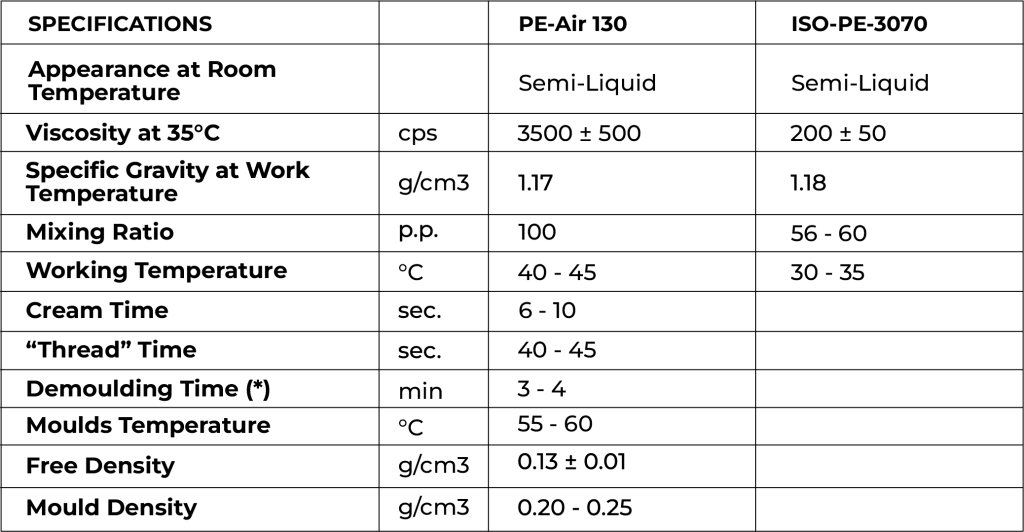

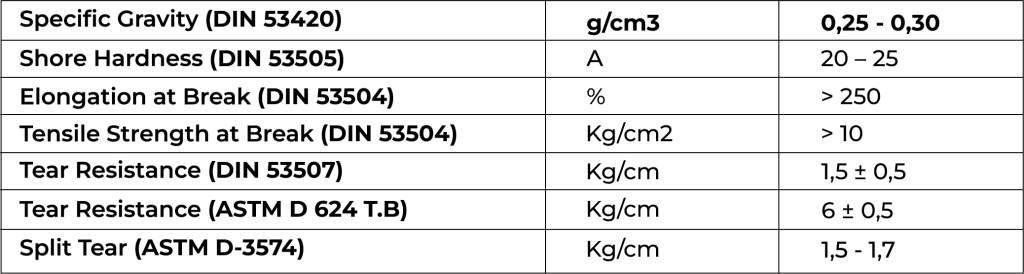

POLYURETHANE FOR

INSOLE

PE-Air 130 / ISO-PE-3070

COMPONENTS

MECHANICAL PROPERTIES OF THE FOAM

Additive for Slab Stock Foam | Catalyst TS-A1

Catalyst TS-A1 is a tertiary amine which has a strong influence on the urea (water isocyanate) reaction in flexible and rigid polyurethane foams.

Key Features and Benefits

- Multi-purpose amine Catalyst.

- Strong gelation catalyst.

- Easy Handling.

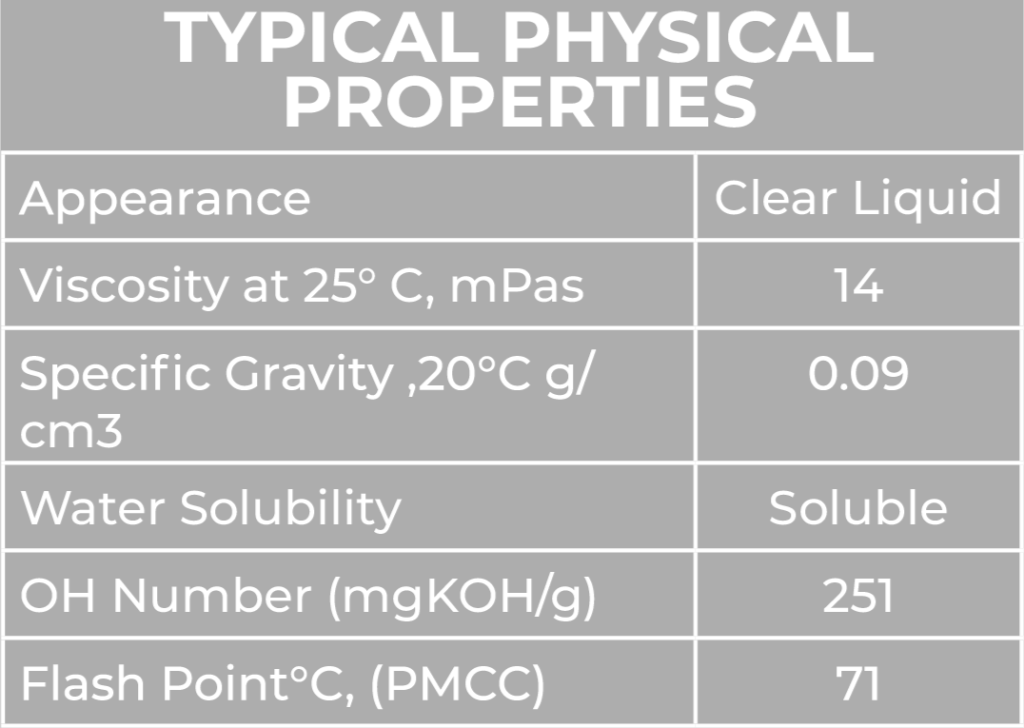

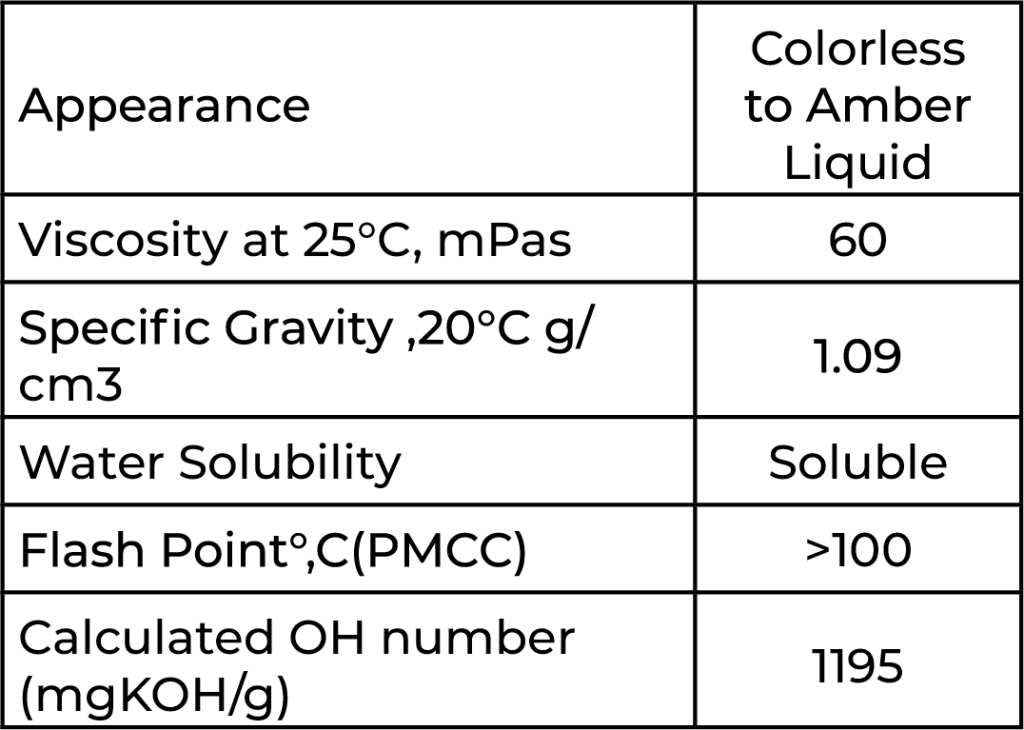

Typical Physical Properties

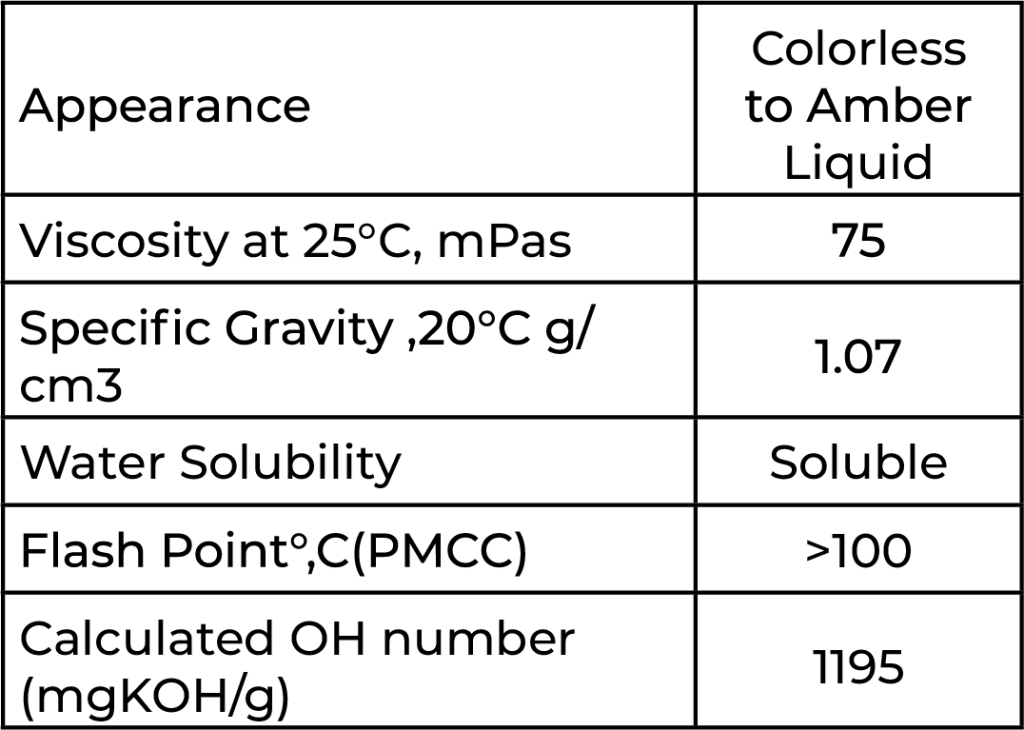

Additive for Slab Stock Foam | Catalyst TS-A33

Key Features and Benefits

- Multi-purpose amine Catalyst.

- Strong gelation catalyst.

- Easy Handling.

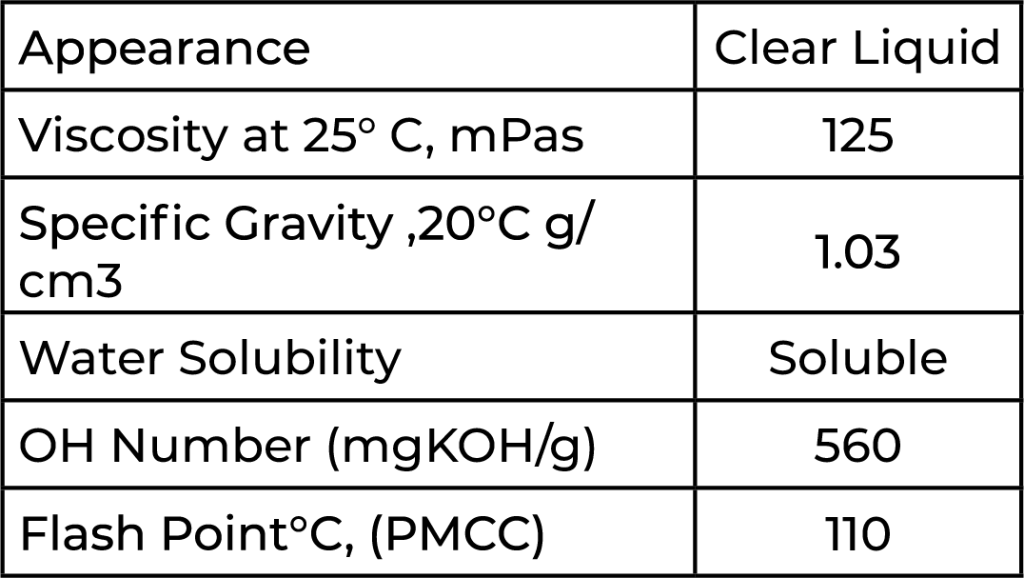

Typical Physical Properties

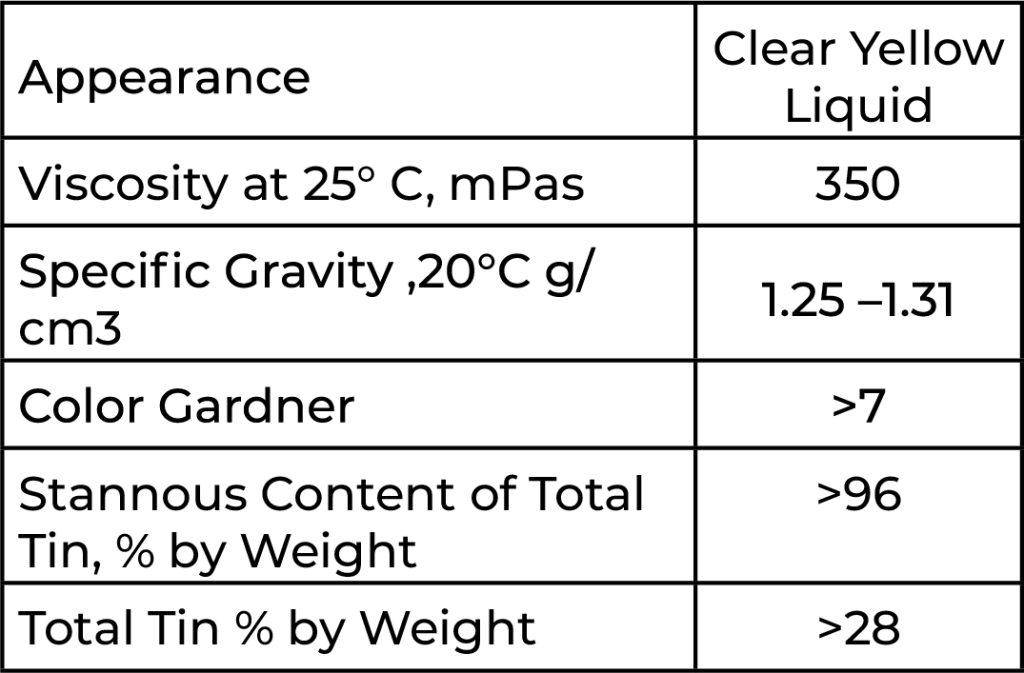

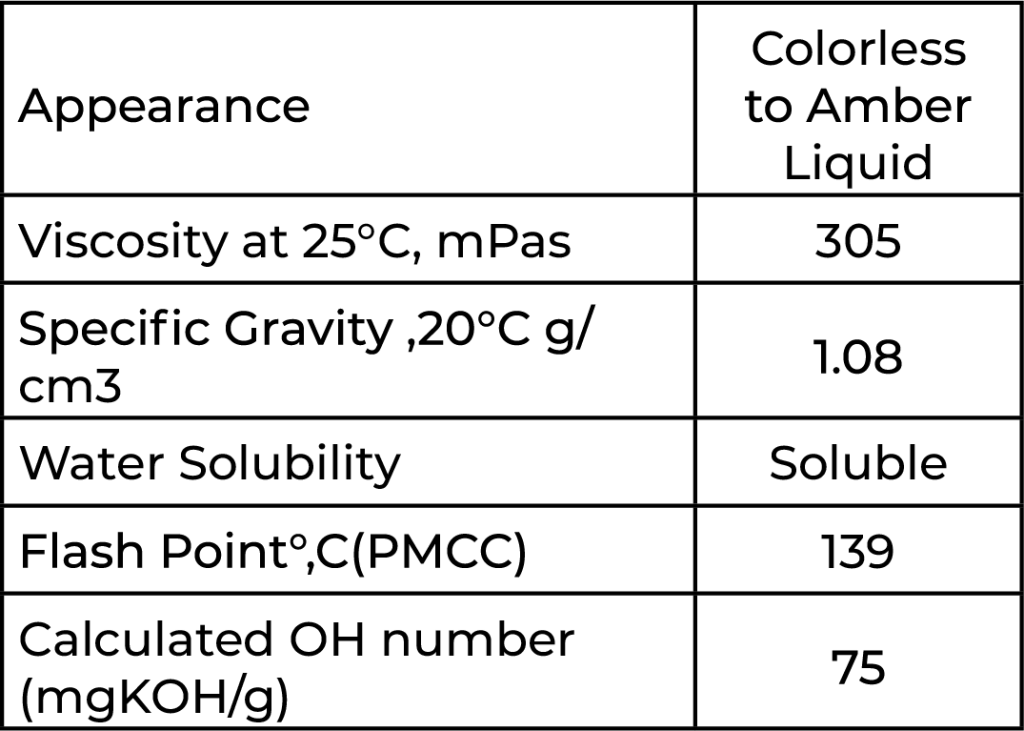

Additive for Slab Stock Foam | Catalyst TS-T9

- Provides excellent high quality, uniform flexible foam

- Its usage ensures economical, high-speed, high- volume foam production

- Provides high gel catalyst activity performance

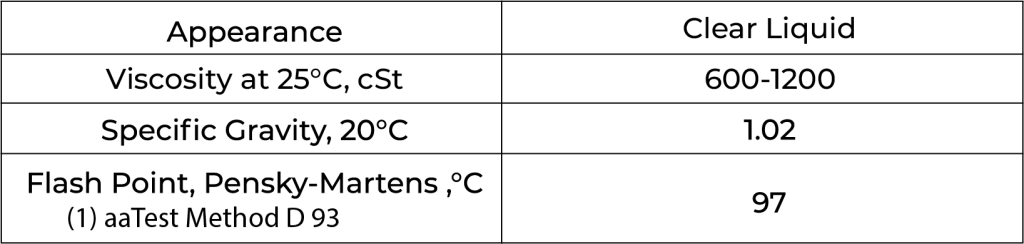

Additive for Slab Stock Foam | Silicon TS-L580

- Silicone with medium efficiency

- Excellent foam stability plus good breathability in low- density formulations blown withnliquid carbon dioxide

- Complete hydrolytic stability in water/amine/silicone preblends

- Works well on all commercially available CO2 equipment (Cardio/Beamech/Novaflex)

Additive for Shoe Grade PU | Catalyst TS-EG

- Strong gelation catalysis

- Convenient liquid form

Additive for Shoe Grade PU | Catalyst TS-1027

- Extremely high reactivity in microcellular systems.

- Increased processing flexibility due to shorter demold time.

Additive for Shoe Grade PU | Catalyst TS-193

- Proven performance in most rigid foam applications, laminated panels.

- Spray foam, pouring-place systems, packaging and bun stock Increased.

- Microcellular foam systems: footwear(shoe soles), integral skin.

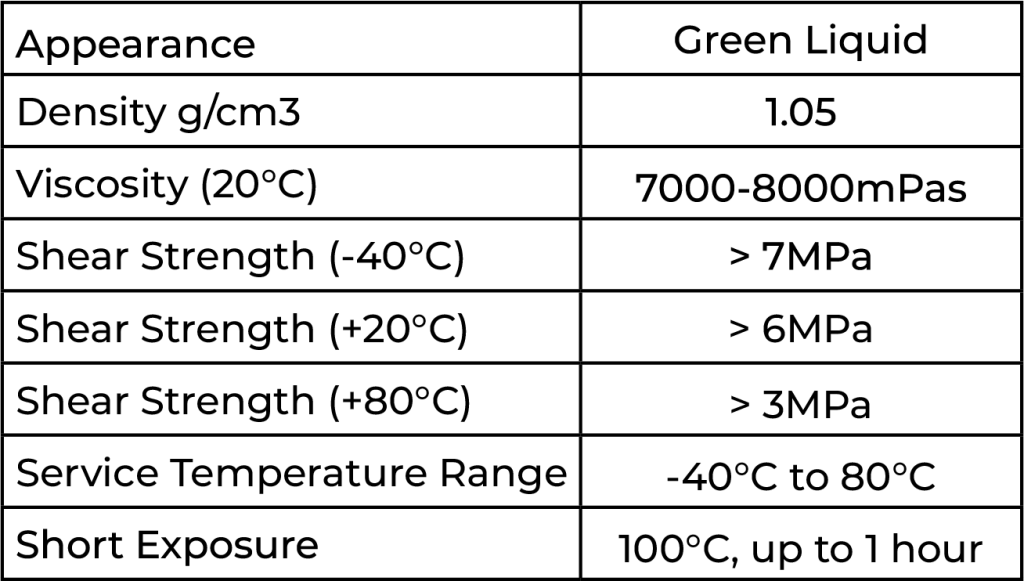

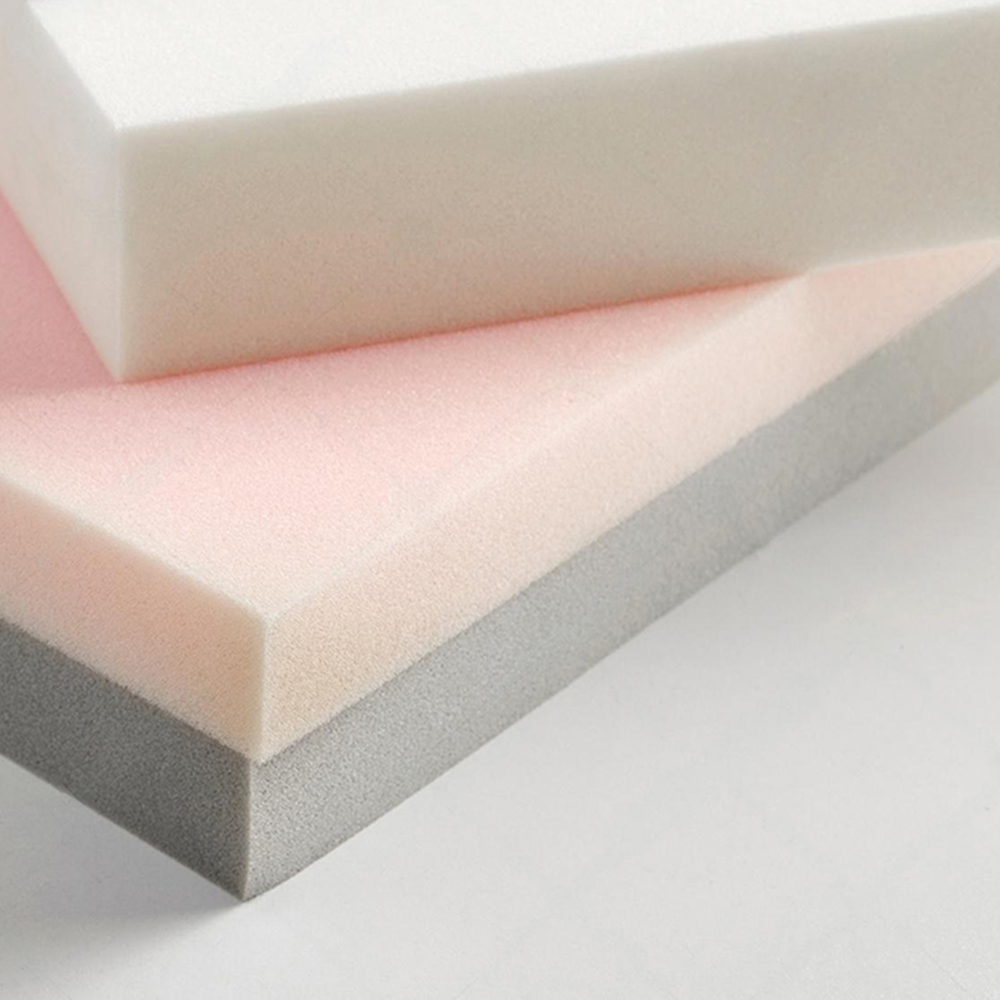

ONE COMPONENT FOAM BINDER 6040

PU Foam binder 6040 is a solvent-free moisture cure one- component adhesive, based on polyurethane technology

Application Areas

The Substance can be bond to one another or to materials. laminated panels, various plastic, rigid doams made for polystyrene, polyurethane and others. The main application area is the manufature of sandwich elements such as partition walls (thermal insulation, sound protection), facade elements with mineral fiber core or mats bonded to primed sheet metal or compression moulding compounds and plaster boards For faster curing PU binder 6040 can be cured in a heated press. Maximum temprerature must not exceed 70°C

Properties and Technical Features

ONE COMPONENT RUBBER BINDER

Application Areas

Rubber binders have a wide range of application areas across industries. In tire manufacturing, they play a vital role in bonding different tire layers, ensuring structural integrity, and enhancing overall performance. Automotive industries utilize rubber binders in the production of belts, hoses, gaskets, seals, and vibration dampeners for secure connections and prevention of leaks. In construction, rubber binders are used in rubberized asphalt, enhancing road durability, flexibility, and skid resistance. Industrial manufacturing relies on rubber binders for conveyor belts, industrial seals, O-rings, and other rubber products requiring strong adhesion and flexibility. The electrical and electronics sector utilizes rubber binders in cables, connectors, and insulating materials for reliable connections and electrical hazard protection. Additionally, rubber binders find application in medical devices like gloves, tubing, and seals, ensuring secure and hygienic bonding of rubber components. These versatile binders contribute to the performance, safety, and durability of various products in numerous industries.

— Ready to start?

Get in Touch

5B CHEM F.Z.C

Plot #E 11, PO Box 932,

Emirates of Ajman UAE

+971504423187

+971505917006

Hamid@waresagroup.com

- Drop Us a Line