SILICONE

TR-L580

Silicone TR-L580 is a non-hydrolyzable silicone, designed to provide excellent foam stability and fine regular cell structure in extremely low density foams using liquid carbon dioxide as the blowing agent. In stretched formulations with high TDI, high water, high CO2, Silicone

TR-L580 provides superior nucleating efficiency and dramatically reduces striations in the foam bun. It has full hydrolytic stability and can be used as a separate stream or in water/ amine/ silicone preblends. Silicone TR-L580 offers enhanced stability while yielding foams with good breathability.

KEY FEATURES & BENEFITS

• Silicone with medium efficiency

• Excellent foam stability plus good breathability in low-density formulations blown with liquid carbon dioxide Complete hydrolytic stability in water/amine/silicone preblends

• Works well on all commercially available CO2 equipment (Cardio/Beamech/Novaflex)

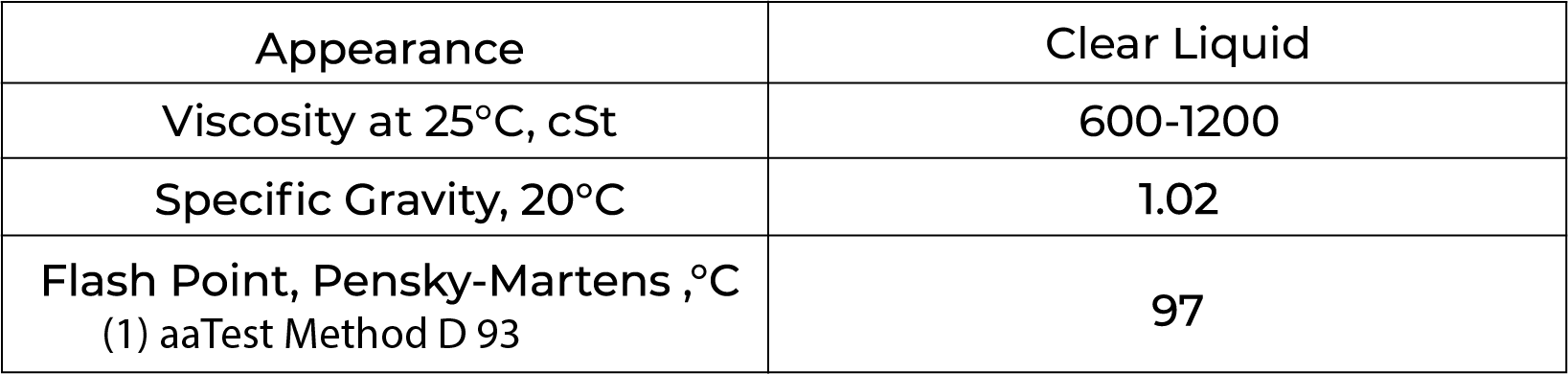

TYPICAL PHYSICAL PROPERTIES

There was, of course, some variability of operating parameters during sample production, but, in most cases, differences were quite small. The exception to this was that a significant throughput difference was required with the Beamech equipment, with the two different polyols. The higher viscosity of the 3500MW polyol required that we increase the surface area

of the sinter (which controls pressure at the lay-down) because pressure was higher than desired. This pressure is the key operating parameter for froth and cell structure control at any given CO2 concentration. Since surface area can only be changed in discrete increments, the resulting pressure was too low at the same throughput used for the 3000MW polyol.

Therefore, it was necessary to significantly increase total throughput to maintain pressure at the desired level. The throughput with 3000MW polyol averaged 11 kg/min, while it averaged almost 19 kg/min using the 3500MW material. For the Novaflex and Cardio equipments, throughput with 3000MW polyol was 14 kg/min and 16 kg/min for the 3500MW material.

PRODUCT SAFETY, HANDLING & STORAGE

Customers considering the use of this product should review the latest Material Safety Data Sheet and label of the product for safety instructions. If you require Technical Data Sheet or Material Safety Data Sheet of any product, please send a request to hamid@waresagroup.com,

we would share the relevant documentation.

LIMITATIONS

Customers must evaluate our Performance Materials products and make their own determination as to fitness of use in their particular applications.

SHELF LIFE